The Mercedes factory seam sealer process uses advanced equipment to apply high-quality sealant, enhancing durability and aesthetics, especially in bumper repair. This technique is crucial for collision repair shops to restore damaged Mercedes vehicles to their original condition, maintaining brand prestige and customer satisfaction. Specialized dispensing equipment streamlines processes, improves accuracy, reduces manual labor time, and catches minor defects early, ensuring vehicle safety and quality finishes akin to tire services or dent removal experts. Technological advancements in car paint services and body repairs revolutionize Mercedes-Benz's excellence reputation, offering faster turnaround times and superior results through precise, efficient sealing.

Mercedes factories utilize a specialized process for applying seam sealers, employing advanced dispensing equipment to enhance efficiency and precision. This innovative approach ensures optimal sealing for every component, critical to maintaining the brand’s reputation for quality and durability. By integrating cutting-edge technology into their manufacturing processes, Mercedes continues to set benchmarks in the automotive industry, guaranteeing seamless, long-lasting results with each vehicle produced.

- Mercedes Factory Seam Sealer: A Specialized Process

- Dispensing Equipment: Enhancing Efficiency and Precision

- The Role of Technology in Seamless Manufacturing

Mercedes Factory Seam Sealer: A Specialized Process

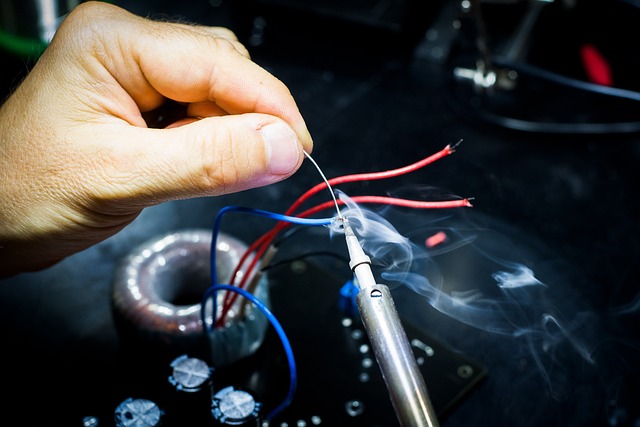

The Mercedes factory seam sealer is a specialized process that plays a critical role in ensuring the durability and aesthetics of Mercedes vehicles. This meticulous procedure involves the application of a high-quality sealant along the seams of various automotive parts, particularly on the vehicle’s body panels and bumpers. The use of advanced dispensing equipment ensures precise and even coating, minimizing waste and maximizing efficiency. This specialized approach not only seals out moisture and corrosion but also enhances the overall look and value of the car.

In a collision repair shop or auto collision center, the Mercedes factory seam sealer is a game-changer. It aids in restoring damaged vehicles to their original condition, providing a seamless finish that matches the manufacturer’s standards. This process is particularly crucial for bumper repair, where maintaining the structural integrity and cosmetic appeal of the vehicle is paramount. By employing this advanced technique, auto collision centers can offer top-tier repairs, ensuring customer satisfaction and retaining the prestige associated with Mercedes brands.

Dispensing Equipment: Enhancing Efficiency and Precision

In the realm of Mercedes factory seam sealing, specialized dispensing equipment plays a pivotal role in enhancing both efficiency and precision. These advanced tools are designed to deliver the exact amount of seam sealer required, ensuring consistent application and minimal wastage. The meticulous process involves precise control over factors like flow rate and pressure, allowing for seamless integration of the sealer into the vehicle’s intricate panels and seams.

By employing these specialized dispensing systems, auto repair services can streamline their processes, reducing the time typically spent on manual application. This not only boosts productivity but also guarantees a higher level of accuracy, particularly in tight or hard-to-reach areas. Moreover, the advanced technology integrated into these tools can help detect and rectify issues early on, ensuring that even minor defects are addressed before they escalate, much like how tire services or dent removal experts use cutting-edge equipment to maintain vehicle aesthetics and safety.

The Role of Technology in Seamless Manufacturing

In today’s automotive industry, technology plays a pivotal role in achieving seamless manufacturing processes. The Mercedes factory seam sealer is a prime example of this, where specialized dispensing equipment revolutionizes the application process. This advanced technology ensures precise and efficient sealing, contributing to the overall quality and durability of car paint services and body repairs. Whether it’s addressing minor dents or major fender benders, these innovations streamline the repair process.

The use of sophisticated machinery and automation reduces human error, resulting in consistent outcomes. This not only enhances productivity but also guarantees a seamless finish, aligning perfectly with Mercedes-Benz’s reputation for excellence. By embracing such technological advancements, car dent repair techniques have evolved, providing customers with faster turnaround times and superior results.

The application of a Mercedes factory seam sealer using specialized dispensing equipment marks a significant step forward in automotive manufacturing. This innovative process not only ensures superior sealing performance but also boosts efficiency and precision on the assembly line. By leveraging advanced technology, manufacturers can achieve seamless finishes, enhancing overall vehicle quality. The integration of precise dispensing systems is a game-changer, allowing for consistent and controlled application of sealers, which is crucial for modern car production.